VVT31 - Adiabatic wall temperature on the edge of an axisymmetric plate

| Solution | Test case |

|---|---|

| Case A | SVTEST264 |

| Case B | SVTEST265 |

Description

The purpose of this validation test is to determine the adiabatic wall temperature of an axisymmetric plate for two cases and to compare the results with the analytical solution:

- Case A: The solver automatically predicts the adiabatic wall temperatures.

- Case B: The solver uses the specified recovery factor to compute adiabatic wall temperature.

Geometry

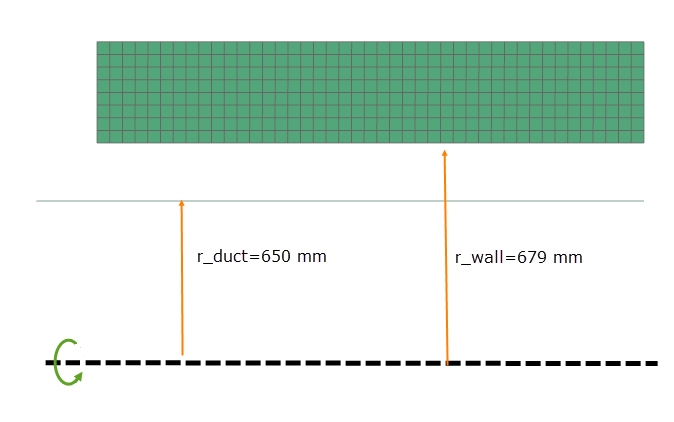

The axisymmetric modeling technique is used to model an axisymmetric plate with a length of 270 mm and a width of 50 mm. A line between the axisymmetric plate and the axis of rotation is used to model a duct with the mass flow. The axisymmetric edge of the plate and the duct are located from the axis of rotation on the distance of 679 mm and 650 mm, respectively.

Simulation model

A 2D mesh is generated using axisymmetric linear quadrilateral elements that are 6.25 mm in size. The 1D elements are axisymmetric ducts with a mass flow.

The meshed elements have the following material and physical properties:

- Shell material for the plate: AISI_310_SS

- Mass density: ρ = 7928 kg/m3

- Environmental fluid material: Air

- Mass density: ρ = 1.2041 kg/m3

- Specific heat at constant pressure : Cp = 1004.5 J/kg·K

The following boundary conditions are applied:

-

Convection Coupling type of the Thermal Coupling - Convection simulation object between the edge of the plate and the duct with the heat transfer coefficient equal to 1e6 Btu/(hr·ft2·ºF).The rotational effects option is set to Correct for Wall Rotation with the swirl ratio equal to 0.1. The Adiabatic Wall Temperature for Heat Transfer Calculations check box is selected.

In Case A: Adiabatic Wall Temperature is set to Automatic and the Specify Recovery Factor check box is cleared.

In Case B: Adiabatic Wall Temperature is set to Automatic and the Specify Recovery Factor check box is selected and Recovery Factor is equal to 0.8914.

- Duct Fan/Pump type of Duct Flow Boundary Conditions applied to the duct with the mass flow of 1 lmb/s.

- Duct Total Pressure type of Duct Flow Boundary Conditions applied to the duct inlet with the total pressure of 384.53 psi.

- Duct Total Pressure type of Duct Flow Boundary Conditions applied to the duct exit with the total pressure of 384.53 psi.

- Temperature constraint applied to the duct nodes with the temperature of 205 °F.

- Model Subset XY type of the Rotation load applied to the 2D plate with the angular velocity of 10000 rev/min.

- Thermal Convecting Zone load applied on the external edge of the 2D axisymmetric plate with the fluid temperature of 205 °F, pressure of 24 bars, the heat transfer coefficient of 0.01 Btu/(hr·ft2·ºF), and the swirl ratio equal to 0.5.

This model uses the Simcenter 3D Multiphysics solver.

The default solver parameters are selected.

Theory

The heat flow between the surface and fluid is proportional to the difference in the temperatures of the wall surface and fluid. The reference fluid temperature is called the adiabatic wall temperature when it causes the wall to have an adiabatic condition, when no heat flux is present.

The adiabatic wall temperature Taw is defined as:

where:

- Ts is the fluid static temperature.

- RF=Pr1/3 is the recovery factor.

- Vϕ=Xsωr is the absolute tangential velocity, where Χs is a swirl ratio, ω is a rotor speed, and r is an edge radius.

The static temperature is defined as:

where:

- Cp is the specific heat at the fluid temperature.

- Tabs is a total absolute temperature.

The specific heat can be assumed constant for the relationship between Ts and Tabs and this equation can be simplified as:

Results

The following table compares the axisymmetric plate's adiabatic wall temperature results predicted by the thermal solver with the calculated theoretical results. Simulation results are in agreement with theoretical values.

| Parameter | Theory | Case A | error (%) | Case B | error (%) |

|---|---|---|---|---|---|

| Taw (°C) | 274.69 | 274.569 | 0.043 | 274.568 | 0.043 |