VVT12 - Hollow cylinder with fixed temperature boundary conditions

| Solution | Test case |

|---|---|

| Finite volume method | SVTEST16 |

| Finite element method | SVTEST242 |

Description

The purpose of this test case is to determine the temperature distribution through the thickness of a hollow cylinder by conductive heat transfer.

Geometry

The hollow cylinder is defined with an inner diameter of 600 mm and an outer diameter of 700 mm. The axisymmetric modeling technique is used, which requires the sketch on the XZ plane. Cylinder thickness is 50 mm, therefore a plate is sketched with the length of 50 mm and height of 10 mm, starting from the inner diameter of the cylinder. A bounded plane is attached to this plate.

Simulation model

This model uses the Axisymmetric Thermal solution type.

A 2D mesh of quadrilateral thin shell elements is generated on the plate surface using 10 mm element size.

The meshed elements have the following material and physical properties:

- Thermal conductivity: k = 1.0 W/m·°C

- Mass density: ρ = 1kg/m3

- Thickness: not required for the axisymmetric thermal analysis

The following boundary conditions are applied:

- Temperature constraint on the inside edge of the cylinder with a value of Ti = 100 ºC.

- Temperature constraint on the outside of the cylinder with a value of To = 20 ºC.

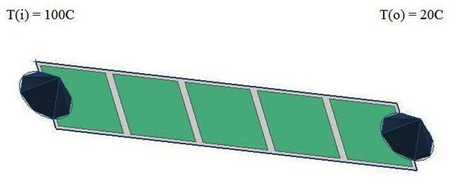

The following figure shows the mesh and the location of the fixed temperature boundary conditions.

The following solution options are set:

- Solution Type=Steady State

- Results Options: Select the heat flux and temperature at nodes and elements.

The default solver parameters are selected.

Theory

The temperature distribution associated with radial conduction through a hollow cylinder is given by [4], [5]:

The heat transfer rates by conduction through the cylinder thickness is determined [4], [5], [6] using the following equations:

The heat flow is determined as follows:

Results

The following table compares the node temperatures computed by the thermal solver with theoretical values.

| Finite volume method | Finite element method | ||||

|---|---|---|---|---|---|

| Rcyl (mm) | Ttheory (ºC) | Tsim (ºC) | Error (%) | Tsim (ºC) | Error (%) |

| 300 | 100 | 100 | 0 | 100 | 0 |

| 310 | 82.98 | 83.12 | 0.17 | 82.98 | 0 |

| 320 | 66.51 | 66.63 | 0.18 | 66.51 | 0 |

| 330 | 50.54 | 50.66 | 0.24 | 50.54 | 0 |

| 340 | 35.04 | 35.16 | 0.34 | 35.04 | 0 |

| 350 | 20 | 20 | 0 | 20 | 0 |

The following table shows the heat transfer rates by conduction through the cylinder thickness.

| Finite volume method | Finite element method | |||

|---|---|---|---|---|

| Rcyl (mm) | qr, (W/m) | Error (%) | qr, (W/m) | Error (%) |

| 305 | 3261.7 | 0.011 | 3261.1 | 0.006 |

| 315 | 3261.5 | 0.007 | 3261.1 | 0.005 |

| 325 | 3261.5 | 0.007 | 3261.1 | 0.005 |

| 335 | 3261.5 | 0.006 | 3261.1 | 0.007 |

| 345 | 3261.5 | 0.007 | 3261.1 | 0.007 |