Troubleshooting thermal convergence issues and invalid temperature distribution

This article describes the various causes of thermal solver convergence issues in simulation models, such as warning 6209 and situations where the conjugate solver fails to converge, or an invalid temperature distribution is detected. It provides detailed methods for diagnosing and resolving these issues.

General guidelines for improving convergence

The following are general steps to take when addressing convergence issues:

- Ensure correct element normals and resolve any geometry problems.

- Ensure thermal couplings are correctly defined and not duplicated.

- Use Deactivation Set Advanced to deactivate sections of the model to identify problematic areas.

- Remove and re-add boundary conditions to identify issues.

Resolving warning 6209

If you encounter Warning 6209 during the thermal analysis:

WARNING 6209**

** Increasing matrix fill value will increase memory consumption and

** CPU time. It is possible this could be averted by improving the

** mesh or improving the model definition.

** Note: Element 2528924 has the largest residual.The following steps may help resolve the issue:

- Check the elements mentioned in the warning. The model elements are in the INPF file and thermal solver created elements are in the <simulation/model name>-<solution/analysis name>_report.log file.

- Improve convergence by:

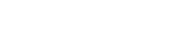

- Adding GPARAM 12 731 -1E36 Card 9 to the

solution, especially when there is high variation in conductance values

due to significant differences in material properties or when some

conductances are considerably larger than others. Matrix diagonal

rescaling helps with the convergence. For models with PCB stacks, this

parameter is particularly effective in aiding convergence.

- Avoiding using a Perfect Contact type thermal coupling. Use a Thermal Coupling instead with a high Heat Transfer Coefficient of 1e5 or 1e6 W/m2 C when defining a coupling representing perfect contact / zero resistance interface, where the mesh does not match.

- Reducing the number of thermal elements if possible.

- Verifying values and units interred for the material proprieties, boundary conditions and solution settings.

- Adding GPARAM 12 731 -1E36 Card 9 to the

solution, especially when there is high variation in conductance values

due to significant differences in material properties or when some

conductances are considerably larger than others. Matrix diagonal

rescaling helps with the convergence. For models with PCB stacks, this

parameter is particularly effective in aiding convergence.

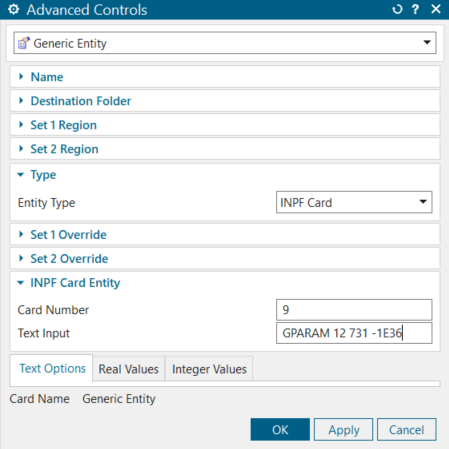

Conjugate-Gradient solver non-convergence solutions

After 100 iterations the Conjugate-Gradient solver did not converge.

Residual=6.070E-06, target residual=1.000E-05, matrix fill= 200

The solution is restarting with matrix fill= 210, iteration limit= 100.The following steps may help resolve the issue:

- Avoid using a Perfect Contact type thermal coupling. Use a Thermal Coupling with a high Heat Transfer Coefficient of 1e5 or 1e6 W/m2 ·C when defining a coupling representing perfect contact / zero resistance interface, where the mesh does not match.

- Add GPARAM 12 731 -1E36 Card 9 to the solution, especially when there is high variation in conductance values due to significant differences in material properties or when some conductances are considerably larger than others. Matrix diagonal rescaling helps with the convergence. For models with PCB stacks, this parameter is particularly effective in aiding convergence.

- Start at a higher initial preconditioner matrix fill value. For example, if the

log file shows that the solver converges later with a fill value of 200, you can

set it directly to this value. If increasing the matrix fill value does not

improve convergence, you can increase the iteration limit to 500 or even

1000.

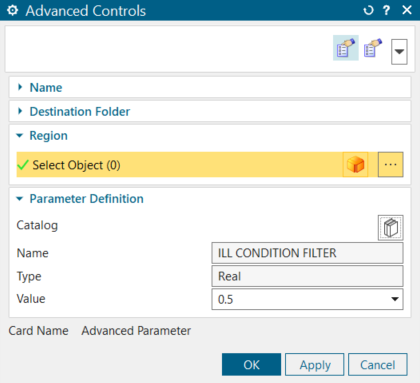

- Use the Ill Condition Filter advanced parameter

(Catalog → Thermal Solver). It

reduces the number of negative conductances created with the CG method, that

helps convergence if there are a lot of 3D elements.

- Remesh the model if there is a poor element quality.

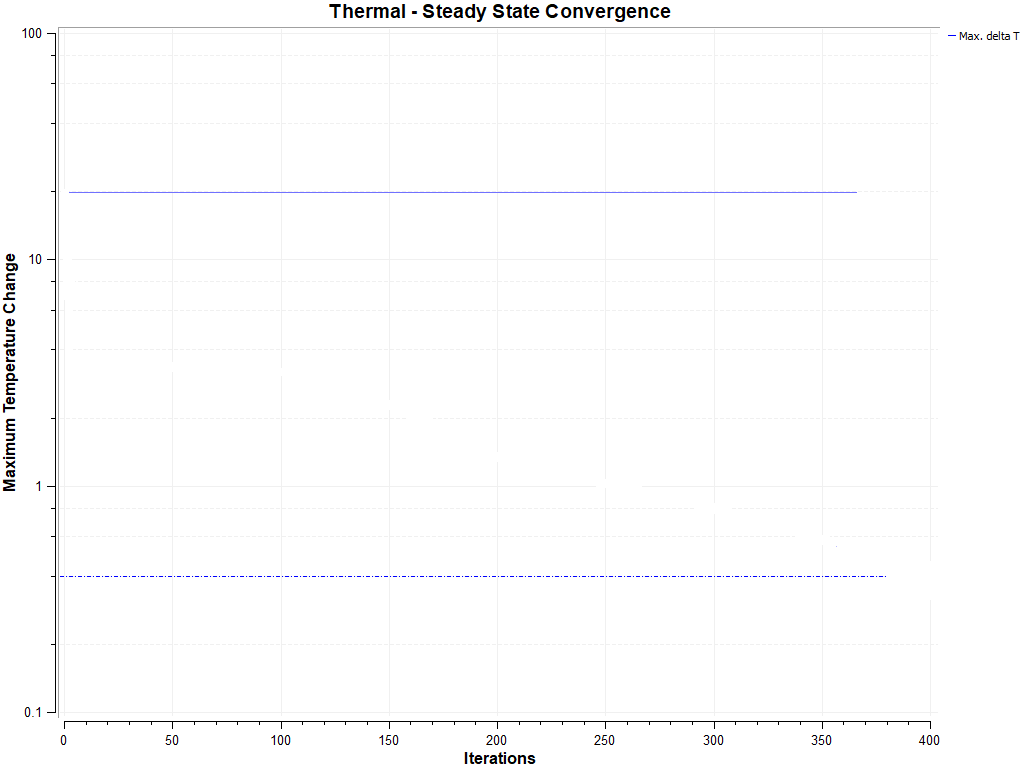

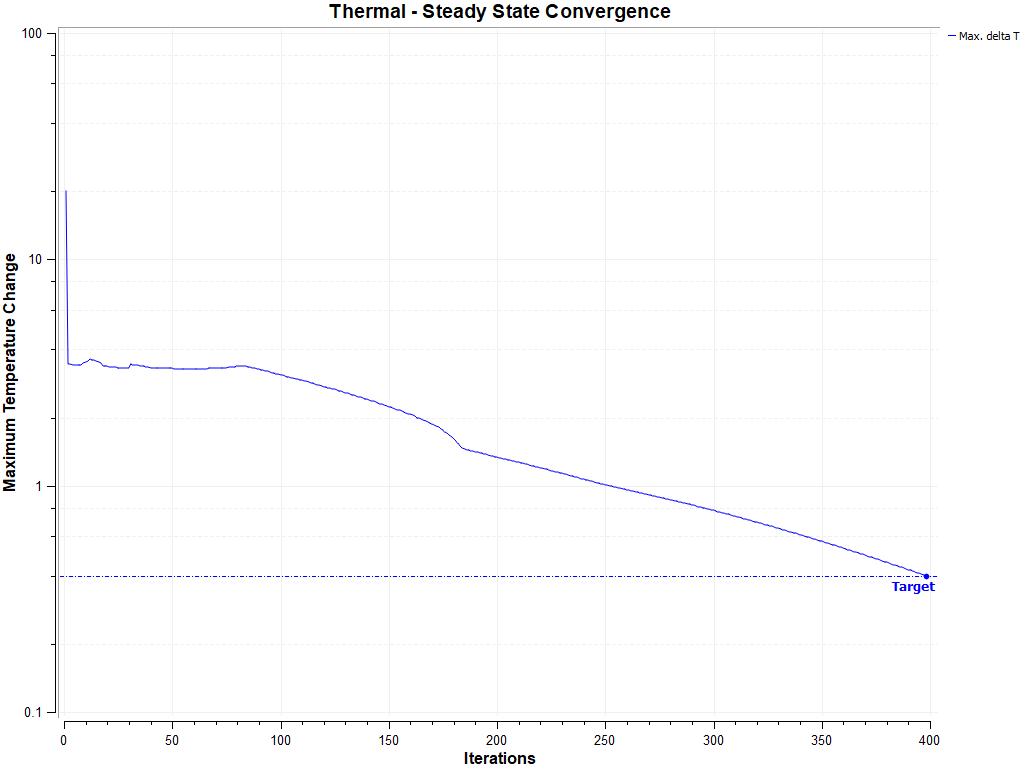

Resolving non-decreasing thermal temperature difference

|

|

| Before reducing relaxation factor | After reducing relaxation factor |

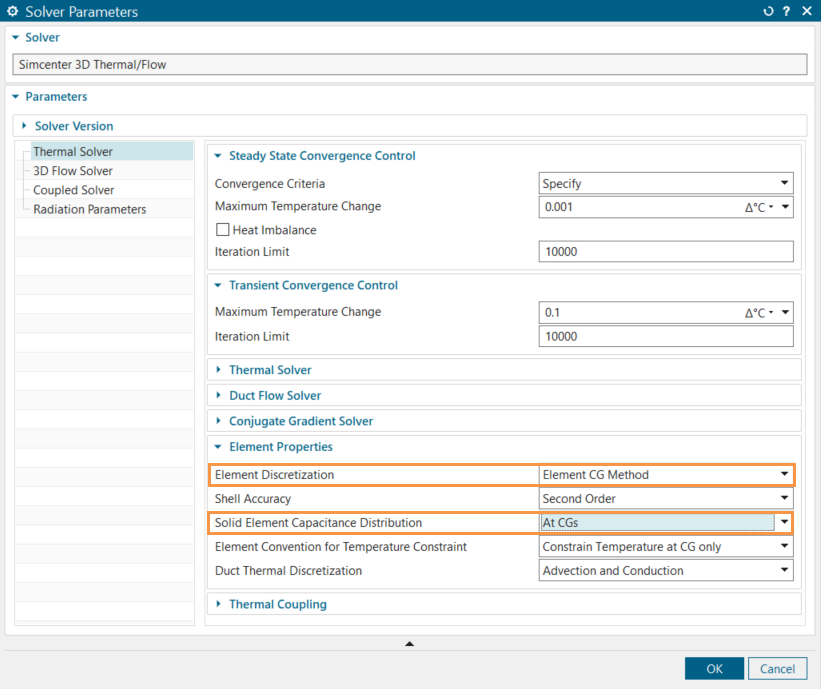

Addressing invalid temperature distribution

If you have issues with the accuracy of temperature distribution, for example problematic situations or spots in temperature for some elements that may have low aspect ratios, which are caused by negative conductivities and capacitance distribution coefficients combined with high temperature gradients in certain directions:

- Select Element CG Method from the Element

Discretization list and set the Solid Element

Capacitance Distribution to At CGs. It

lumps the capacitance and elemental heat load at the center of gravity (CG), not

at the boundary elements, and creates conductances from CG to boundary

elements.