How to model transmissivity through explicitly modeled 3D coating layers?

This article explains how to set up transmissive radiation through multiple layers of 3D elements in hybrid 2D-3D models for turbomachinery applications. It compares three cyclic symmetry models with different layer-to-layer thermal contact definitions: mesh mating , high heat transfer coefficient (HTC), and perfect contact.

Introduction

Although Simcenter 3D provides a Protective Layers simulation object to model coatings, it is not suitable for transmissive radiation modeling. Only the surface of the outer protective layer exchanges radiation. In contrast, to capture transmissive radiation, model the coating layers as explicit 3D bodies and apply 2D surface coats on their exposed faces. The 2D surface coats carry the thermo-optical properties, such as emissivity, reflectivity, and transmissivity, and participate in the radiation enclosure, while the 3D solids provide the through-thickness conduction path.

Model setup

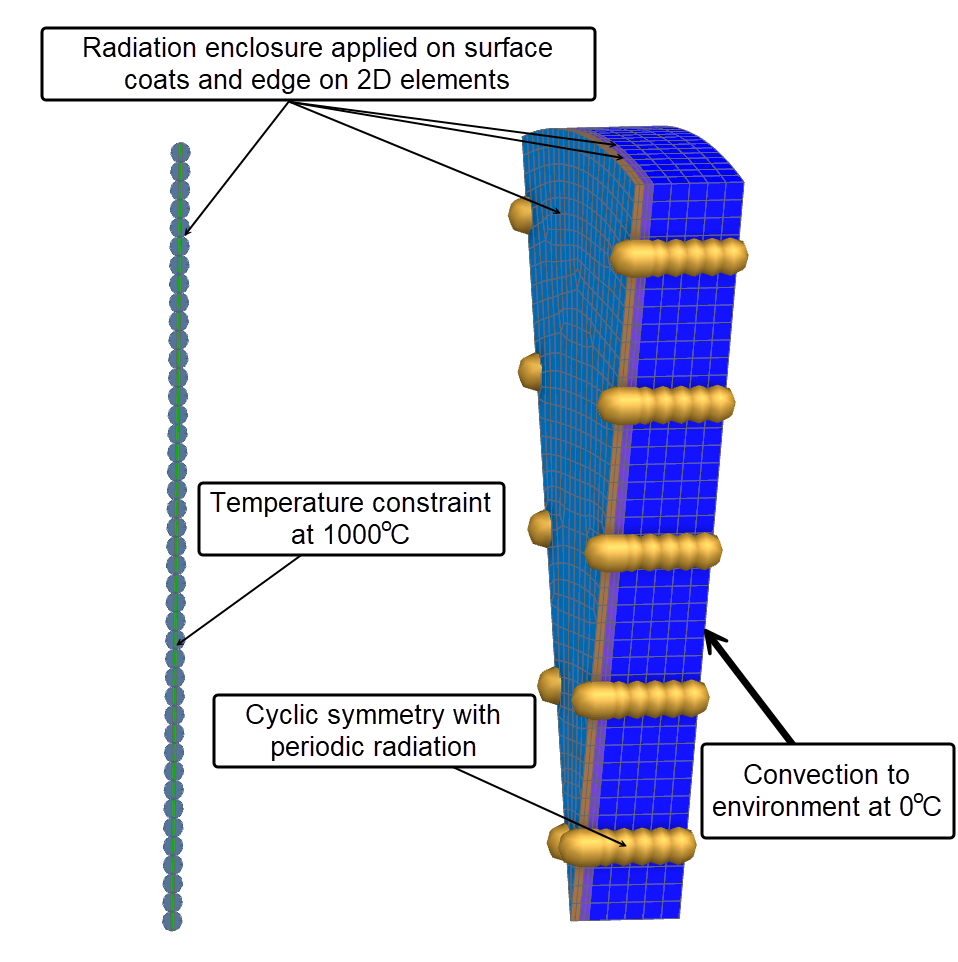

- Geometry and mesh

-

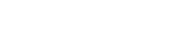

The model combines different element types to represent a hybrid 2D-3D configuration:- 3D elements represent the bulk materials, including the base metal, bond coat, and top coat.

- 2D surface coats are applied to the outer surfaces of 3D solids

to capture radiation exchange.

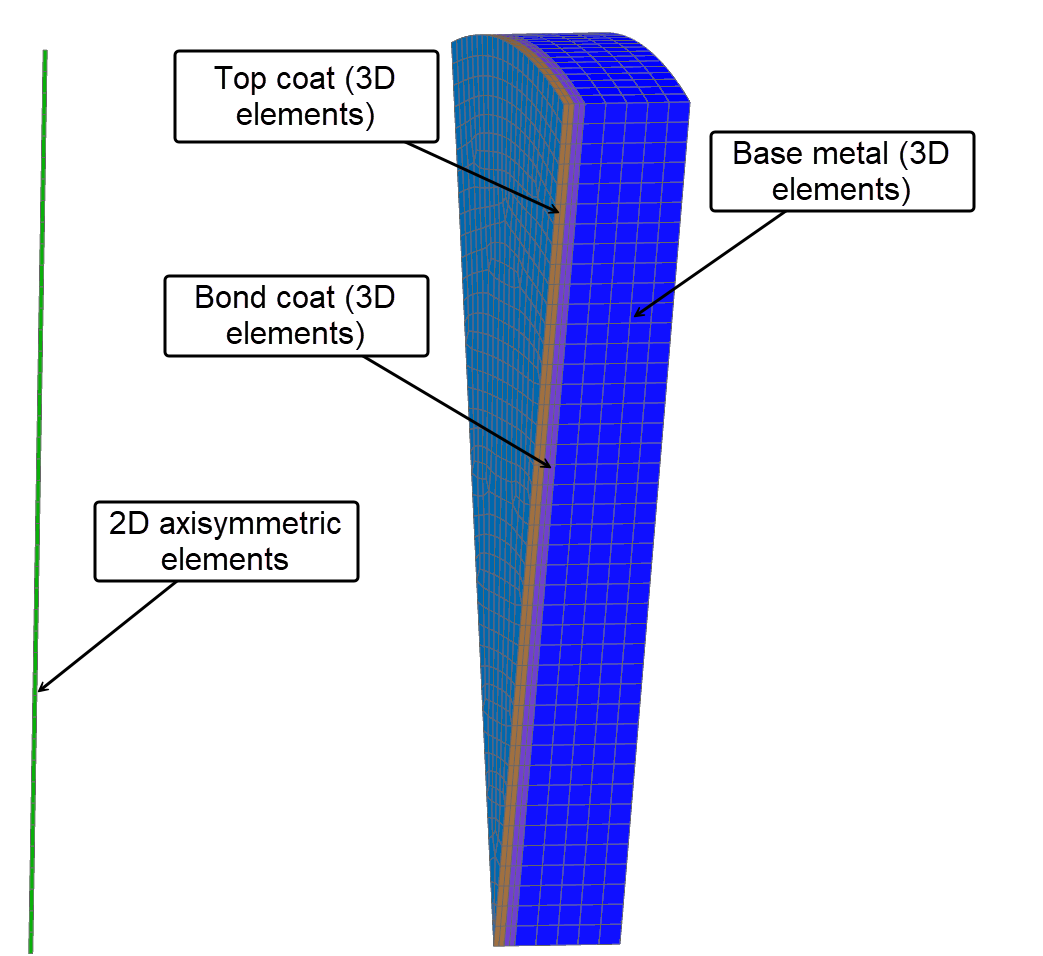

- 2D transmissive surface coatings with a transmissivity of 0.95.

- 2D base material surface coating with an emissivity of 0.8.

- 2D axisymmetric elements are used only in hybrid 2D–3D models, typically for turbomachinery applications, where an axisymmetric source region exchanges radiation with a 3D cyclic sector.

- Assumptions

-

- Two thermal barrier coating layers are modeled.

- Radiation occurs in the infrared (IR) spectrum.

- Radiation heat flow occurs at 2D surface coatings attached to the 3D solid.

- Heating due to internal radiation within 3D elements is not considered.

- Boundary conditions

-

- Cyclic symmetry with enabled radiative thermal rotational

periodicity. The thermal solver internally expands the modeled

cyclic sector into a full 360° representation.

In Thermal Solution Parameters, increase the Number of Axisymmetric Segments to 32 to better control the expansion of axisymmetric elements.

- Temperature constraint of 1000 °C applied to the base metal.

- Convection to environment at 0 °C applied to the external environment.

- Radiation enclosure applied to coating surfaces and edges of 2D

axisymmetric elements.

- When using the Monte Carlo method, increase the number of rays from the default 2000 to 10,000 or higher for stability and accuracy.

- Surface selection: top selection includes two 2D transmissive coating surfaces, 2D base material surface coating, and 2D axisymmetric elements; bottom selection includes two 2D transmissive coating surfaces.

- Thermal contacts are defined at the geometric interfaces between coating layers: one between base metal and bond coat, and another between the bond and top coat. Model each interface using perfect contact, high heat transfer coefficient, or mesh mating.

- Cyclic symmetry with enabled radiative thermal rotational

periodicity. The thermal solver internally expands the modeled

cyclic sector into a full 360° representation.

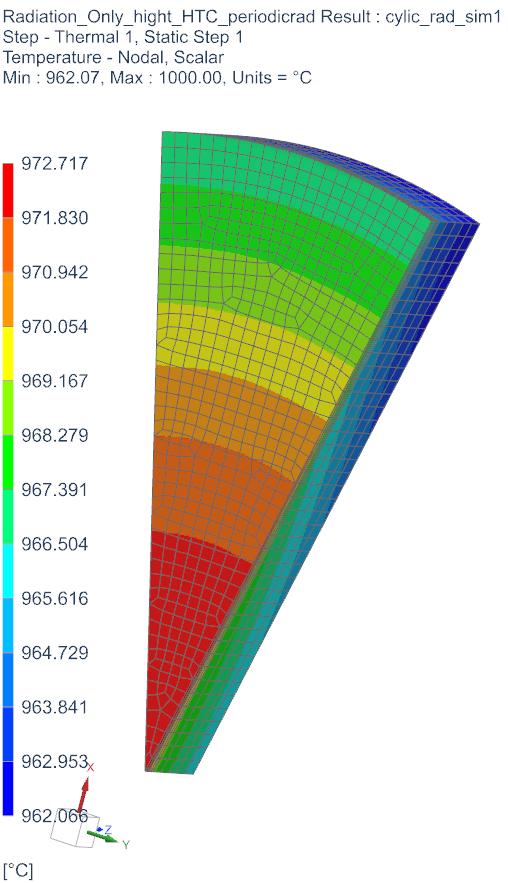

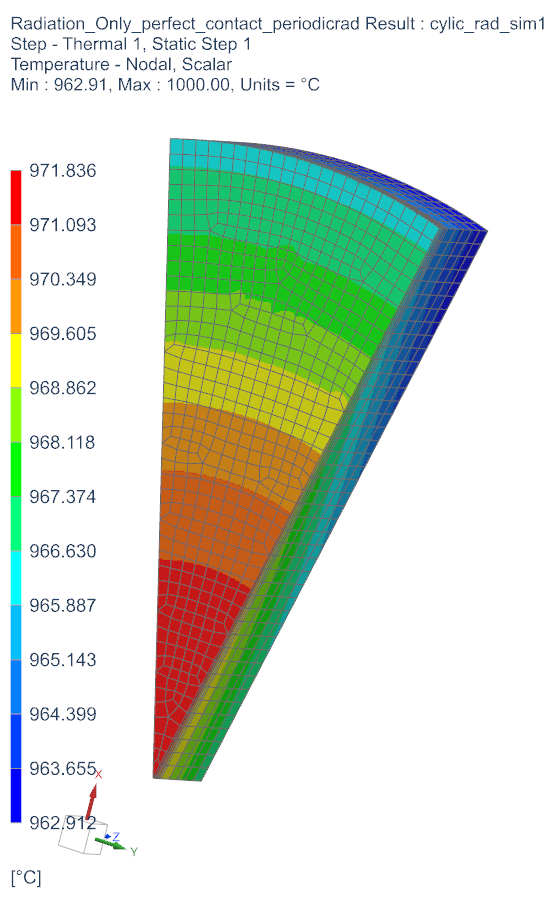

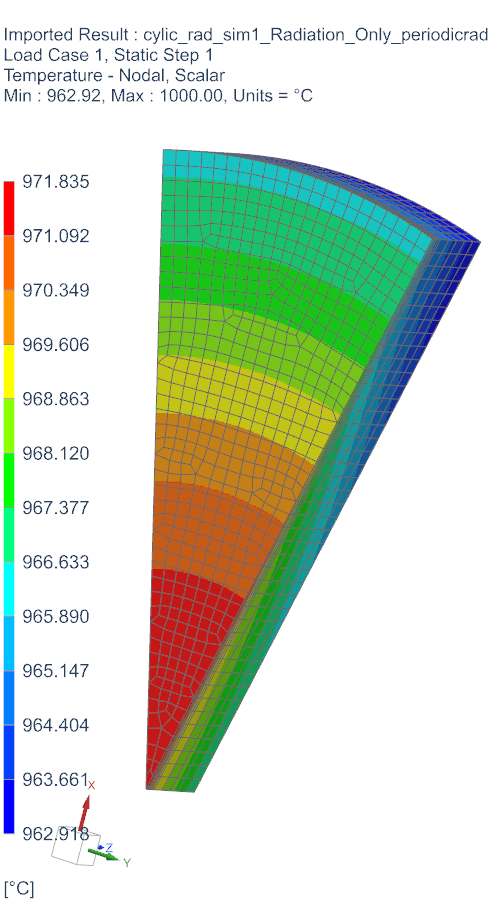

Results

The simulation confirms that temperatures align consistently across coating layers in all methods.

| High HTC | Perfect contact | Mesh mating |

|

|

|

| Reasonable alignment but small offsets at contour extremes. Risk of thermal bridging when large temperature gradients exist. | More stable than high HTC, but requires additional setup. | Most accurate and stable. Aligns well with analytical predictions and avoids artificial offsets. |

Recommendation

- Mesh mating avoids artificial temperature offsets and simplifies model preparation.

- Temperature distributions across layers align closely with analytical predictions.

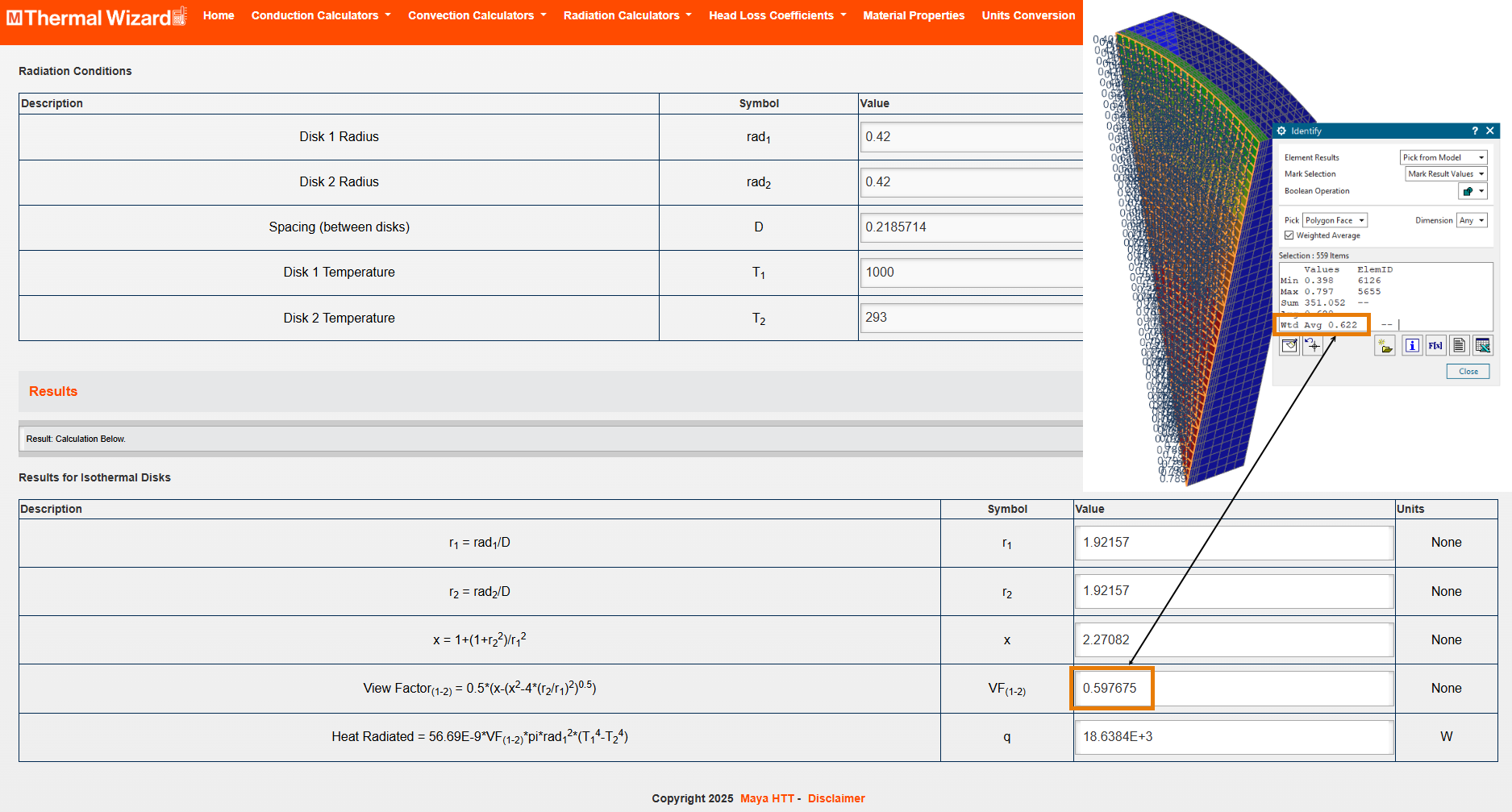

- Radiation view factor matches within 4% of hand calculations, which is validated with the Maya Thermal Wizard.