Thin perforated plate screen correlation

The flow solver uses the following thin perforated plate screen correlation to compute the head loss coefficient for perforated thin plates with sharp, rounded, or beveled edge orifices using the free area ratio of the studied geometry.

For this geometry the following correlation applies:

The term, h', depends on the geometry of the perforations from the screen. To obtain, h', you can select between the following edge geometries: sharp edge, rounded edge, beveled edge.

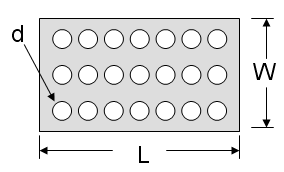

The following definitions are used to define the thin perforated plate:

- L is the length of the screen.

- W is the width of the screen.

- d is the diameter of a single orifice.

- P0 is the perimeter of a single orifice.

- A0 is the area of a single orifice.

- AFS = LW is the area of the free stream.

- is the free area ratio.

- t is the thickness of the plate.

- dh = 4A0/P0 is hydraulic diameter of a single orifice.

- U is the viscosity of the fluid.

- Red = Vn dn/v is the orifice Reynolds number.

Sharp Edge

The term, h', for sharp edge orifice is:

The following assumptions apply:

- t/dh < 0.015

- Red > 105

Rounded Edge

The term, h', for rounded edge orifice is:

The following assumptions apply:

- Grid thickness is the same as orifice radius.

- Red > 103

Beveled Edge

The term, h', for beveled edge orifice is:

The following assumptions apply:

- The beveled edge of the orifice is facing the flow.

- The bevel angle is between 40° and 90°.

- 0.01 < t/dh < 0.16

- Red > 104